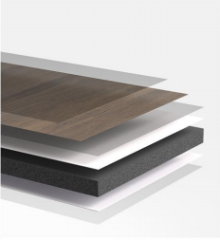

High quality aluminium composite panel

BAFONI high quality aluminium composite panel with high quality raw materials

PVDF coating ACP warranty 15 years

More than 20 years ACP manufacture experience

50,000.00 M2 factor area and the most advance aluminium cladding panel production lines

- BAFONI

- GUANGDONG

- 10DAYS

- 1000000m2 /per year

Details

High quality BAFONI aluminium composite panel basic information:

| Brand | BAFONI |

| Coating | PVDF, PE with PPG, BECKERS,VALSPAR paint |

| Core | Fireproof A2, B1 , unbroken normally plastic |

| Colors | Any colors as your request |

| Macromolecular lamination film | DUPONT materials with 0.6mm thickness |

| Protective film | Easy remove glue with 0.8mm thickness |

| Standard size | 1220X2440MM |

| Max width | 2000MM |

| Max length | Any length as your request |

| Warranty | 15 years for PVDF(outside ), 8 years for PE (inside) |

About BAFONI aluminium cladding panel factory :

BAFONI since 2002, factory area 50000M2 with the most advanced production equipment and technological. 15 years quality guarantee.

At BAFONI, we take pride in being a leading manufacturer of high-quality aluminum composite panels, Solid aluminium panels and aluminium coating coils for a wide range of industries and applications. With more than 20 years of experience and a commitment to excellence, we have established ourselves as a trusted partner for businesses seeking durable, versatile, and aesthetically pleasing building materials.

Our state-of-the-art manufacturing facility boasts advanced technology and a dedicated team of professionals, enabling us to deliver superior ACP products that meet the highest industry standards. We source only the finest raw materials to ensure the exceptional quality and longevity of our panels. With a relentless focus on precision and craftsmanship, we guarantee consistent product performance and durability.

Our aluminum composite panels are renowned for their versatility and adaptability. Whether you require ACP for architectural cladding, signage, interior decoration, or any other application, our panels offer unmatched functionality and aesthetics. With an extensive range of colors, finishes, and textures available, we provide endless design possibilities to enhance the visual appeal of your projects.

At BAFONI, we are committed to sustainability and environmental responsibility. Our ACP products are manufactured using eco-friendly processes and materials, ensuring minimal impact on the environment. We adhere to rigorous quality control measures throughout the production process, ensuring that our panels are not only visually striking but also highly durable and weather-resistant, making them suitable for various climates and challenging conditions.

Customer satisfaction is at the heart of our business. We understand that each project is unique, and we work closely with our clients to deliver customized solutions that meet their specific requirements. Our dedicated customer support team is always ready to assist you, providing technical guidance, product information, and prompt assistance at every stage of your project.

Choose BAFONI as your preferred ACP manufacturer and elevate your projects to new heights of excellence. Contact us today to explore our extensive range of aluminum composite panels and discover how our innovative solutions can transform your vision into reality.

BAFONI: Redefining possibilities with premium aluminum composite panels.

BAFONI ACP production detail:

50,000M2 factory manufacture area, with the most advance 2 aluminium coating lines,3 aluminium composite panel lines, 1 solid aluminium panel power coating line.Annual output quantity 4,000,000.00M2 per year.

Certifications:

Certifications:

BAFONI high quality loading Package :

BAFONI high quality loading Package :

BAFONI high qality aluminium cladding panel projects:

How to identify high quality aluminium composite panel ;

Identifying high-quality aluminum composite panels (ACP) involves assessing various factors related to their composition, construction, and performance. ACP is commonly used in architectural cladding, signage, and other applications. Here are some key factors to consider when evaluating the quality of aluminum composite panels:

Core Material:

High-quality ACP typically has a fire-resistant core. Common core types include polyethylene (PE), fire-resistant (FR), and non-combustible (e.g., mineral-filled or aluminum honeycomb). FR and non-combustible cores are preferred for applications where fire safety is a concern.

Thickness:

Thicker panels generally offer better rigidity and durability. Common thicknesses range from 3mm to 6mm. Thicker panels are often preferred for applications requiring higher strength and resistance to deformation.

Aluminum Skin Thickness:

The thickness of the aluminum skins on both sides of the core contributes to the overall durability of the panel. Thicker aluminum skins are generally associated with better quality.

Coating Quality:

The quality of the surface coating influences the ACP's resistance to weathering, corrosion, and fading. Look for panels with high-quality PVDF (polyvinylidene fluoride) or FEVE (fluoroethylene vinyl ether) coatings, as they offer excellent durability and color retention.

Surface Flatness:

Check the panels for surface flatness and smoothness. High-quality ACP should have a consistent and smooth surface without wrinkles, bubbles, or irregularities.

Color Uniformity:

Inspect the color consistency across the entire panel. High-quality ACP should exhibit uniform color without noticeable variations.

Weather Resistance:

ACP should be resistant to weather conditions, UV radiation, and temperature fluctuations. Panels with high weather resistance will maintain their appearance over an extended period.

Installation System:

Consider the type of installation system used. A reliable and high-quality installation system enhances the overall performance and longevity of the ACP.

Certifications and Standards:

Look for panels that comply with industry standards and certifications. For example, panels meeting fire safety standards (such as ASTM E84 or EN 13501) are preferred.

Manufacturer Reputation:

Choose ACP from reputable manufacturers with a history of producing quality products. Research the manufacturer's reputation, read customer reviews, and check if they adhere to industry standards.

Warranty:

A longer warranty period often indicates the manufacturer's confidence in the product's quality. Check the warranty terms and conditions for specific coverage details.

By carefully considering these factors, you can better assess the quality of aluminum composite panels and make an informed decision based on your specific requirements.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)